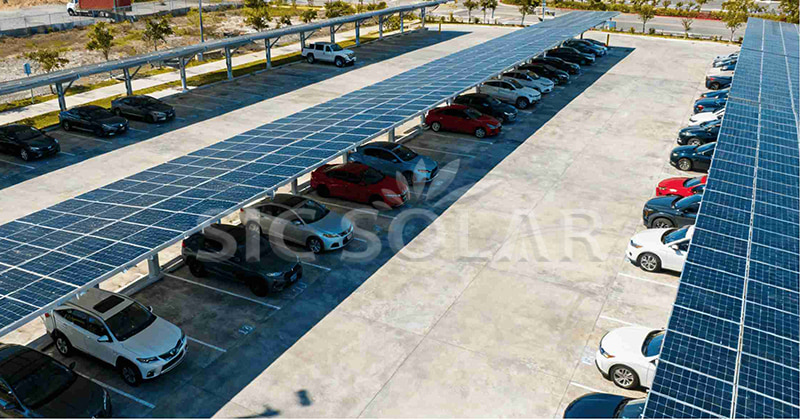

Solar carports have become a popular way to combine renewable energy generation with functional parking space. They offer shade, protection for vehicles, and a steady supply of clean electricity. While the benefits are clear, solar carports also come with several challenges that are worth considering before making an investment. Understanding these disadvantages can help homeowners and businesses make better decisions when planning solar installations.

One of the most noticeable drawbacks of solar carports is their high upfront cost. Unlike rooftop solar systems that use existing structures, carports require building a new support framework strong enough to hold multiple solar panels and withstand environmental stresses such as wind or snow. This means additional materials, engineering, and construction expenses, which can make solar carports significantly more expensive to install.

Another limitation is the space requirement. Solar carports need a dedicated area large enough to accommodate both vehicles and the solar panels above. In dense urban environments or small properties, available space may be limited. The size and layout of the parking lot can also affect the system’s orientation and, therefore, its overall energy production efficiency.

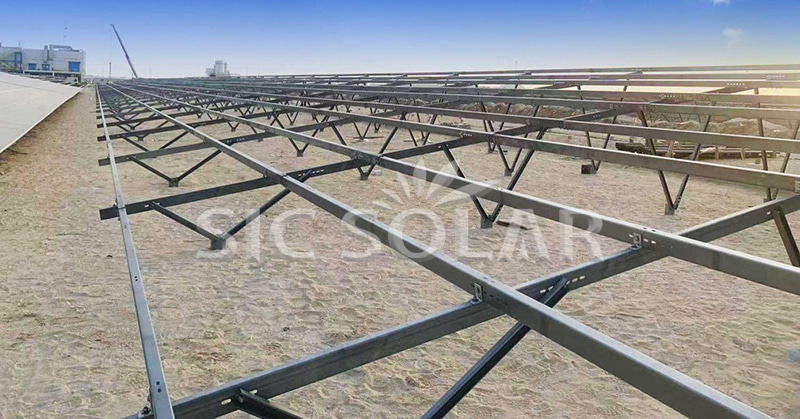

Installation complexity is another consideration. Building a solar carport involves not only electrical work but also civil and structural engineering. The process can take longer than rooftop installations and may require specific building permits and design approvals. Weather conditions or soil stability can further complicate construction, leading to extended project timelines.

Maintenance and cleaning can also be slightly more demanding. Because carports are elevated structures, accessing the panels for inspection or cleaning may require specialized equipment. Although maintenance needs are minimal, they can still add to operational costs over time.

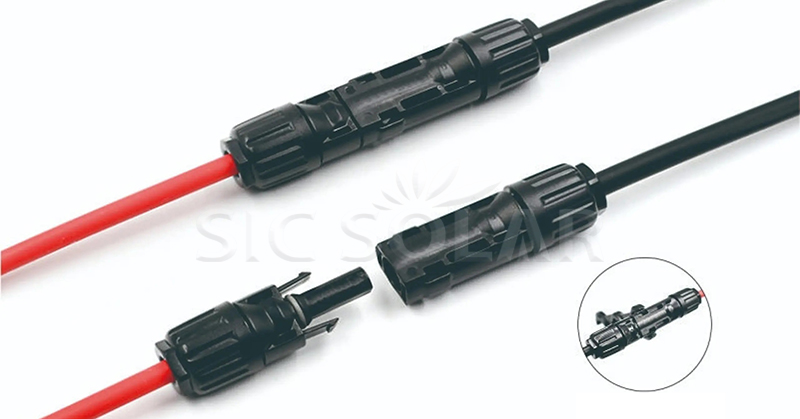

Companies like SIC Solar, a global manufacturer of photovoltaic mounting systems, address some of these challenges by developing efficient and durable carport structures. Their systems use high-strength aluminum and galvanized steel to ensure long-term reliability and easier installation. Designed for various parking layouts, SIC Solar’s mounting solutions can reduce installation labor and improve system stability, helping to offset some of the disadvantages associated with solar carports.

Another concern involves aesthetic and zoning restrictions. Some property owners worry that large steel structures could affect the visual appeal of their premises or face limitations from local regulations. However, modern designs are increasingly sleek and adaptable, blending well with both residential and commercial environments.

Despite these challenges, solar carports continue to attract attention because they serve dual purposes—energy production and vehicle protection. While their disadvantages mainly center around cost and complexity, advances in design and manufacturing, like those pioneered by companies such as SIC Solar, are gradually making these systems more accessible and efficient for widespread use.

...