As the demand for renewable energy grows, innovation continues to shape how and where solar power can be generated. One of the most exciting developments in recent years is the floating solar array. Unlike traditional rooftop or ground-mounted systems, floating solar involves installing solar panels on bodies of water such as lakes, reservoirs, ponds, or even dams. This unique approach addresses land constraints while unlocking new benefits for both energy and the environment.

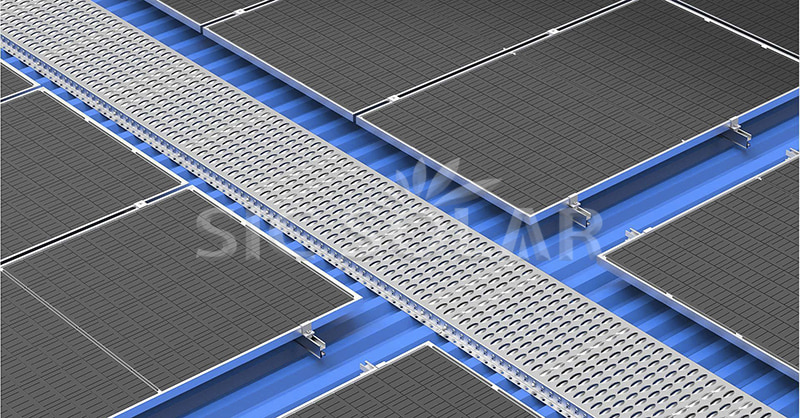

A floating solar array consists of photovoltaic panels mounted on buoyant platforms that rest on the water’s surface. These platforms are anchored to the bottom or shoreline to keep the system stable. Electrical components and inverters are either placed on nearby land or integrated into floating structures. The result is a solar power plant that efficiently converts sunlight into electricity without occupying valuable land space.

One of the biggest advantages of floating solar is land conservation. In densely populated regions, finding suitable land for large-scale solar farms can be a challenge. By using underutilized water surfaces, floating solar frees up land for agriculture, housing, or other infrastructure needs.

Another benefit is increased efficiency. Water has a natural cooling effect on the solar panels, helping them operate at lower temperatures compared to ground-mounted systems. This cooling reduces heat-related efficiency losses, meaning floating panels often generate more electricity over time.

Floating solar arrays can also help reduce water evaporation from reservoirs and ponds, which is particularly valuable in hot or drought-prone regions. The panels provide shade, slowing down evaporation rates while also limiting algae growth that can negatively impact water quality.

From an environmental perspective, floating solar systems minimize habitat disruption since they are built on existing water bodies rather than clearing new land. They also integrate well with existing hydroelectric dams, allowing hybrid systems that combine solar and hydro power.

The durability and safety of a floating solar array depend heavily on the mounting structures used. The platforms must withstand waves, wind, and changing water levels while keeping the panels securely in place. Companies such as SIC Solar, which specializes in manufacturing and selling photovoltaic mounting brackets, play an important role in advancing this technology by providing robust and adaptable solutions. Their expertise ensures that solar panels can perform reliably even in challenging aquatic environments.

Floating solar is not just a clever solution to land shortages—it represents the next step in expanding renewable energy capacity worldwide. By harnessing the untapped potential of water surfaces, it offers a sustainable, efficient, and innovative way to generate clean power for the future.

...